The process started with the removal of the old roofing membrane and some rooftop demolition. For most large roofs like this, there would be multiple access points and the rig would be relatively simple. In this case, because of the shape of the layout, there was really only one access point to the top of Building 64, and it had an obstructed view to the ground below. A 50-foot scaffold tower was erected to get the crew and equipment to the top. When the crane was needed to assist with the demolition process, there was no line of sight between the operator and material being demolished. Signalers were positioned above obstructions with a better vantage point to direct the crane operator. Expertise and trust came into play as the crew on the roof used walkie-talkies to guide the crane operator to success.

After the flashing membrane was removed, there was some obvious decay to the masonry along parapet walls, so Cleveland Building Restoration was called in to repair the masonry deficiencies, providing a solid substrate for Warren Roofing® to wrap up.

The surface below the membrane is, in essence, a layer of concrete. A temporary membrane was used to protect that concrete against weather damage while the permanent membrane was being put in place.

Nate selected a fleece-backed PVC membrane from Johns Manville to complete the project. This waterproof membrane is adhered to a 1/2-in. thick gypsum board, called DEXcell® improving puncture resistance and wind uplift, beneath that is a layer 3-1/2” insulation, adding R-value to the roof system. This roof system provides superior protection from high winds and cold weather, something Cleveland is known for.

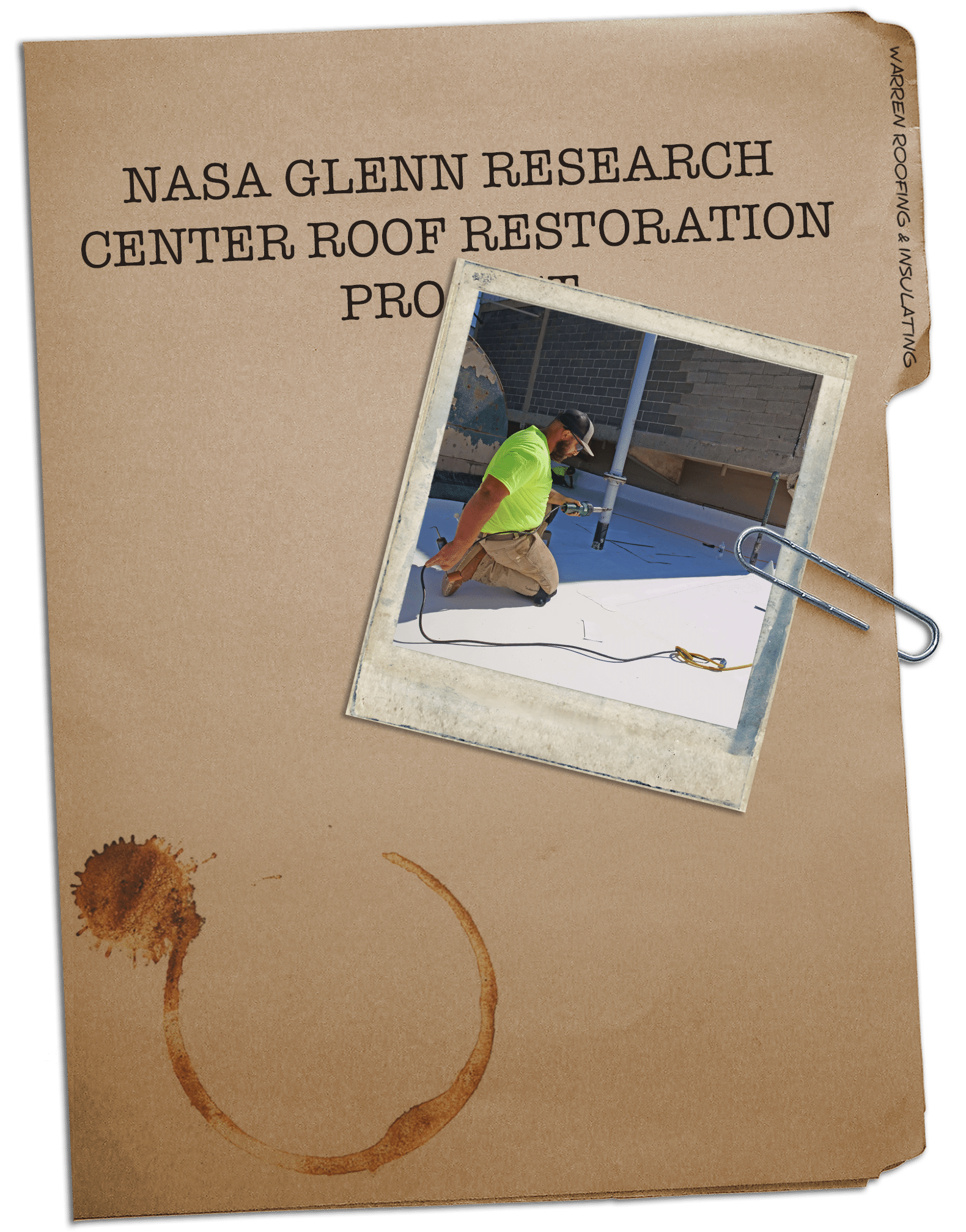

The membrane, coverboard, and insulation is adhered using a two-part polyurethane adhesive. The seams of the permanent membrane were then heat-welded with a LEISTER heat gun to complete the sealing and further protect against water damage.

The temporary roof membrane isn’t removed as part of this process. The temporary roof membrane was torch-fused directly to the concrete deck and will be left in place as a permanent vapor barrier. This vapor barrier prevents moisture drive from the inside of the building.